The BMC kneading machine is a special equipment for preparing the BMC (Bulk Molding Compound) mixture. The equipment can mix and knead raw materials such as unsaturated polyester resin, filler, glass fiber, additives, etc., efficiently and uniformly to form a semi-fluid BMC mass suitable for the molding process.

Working Principle of the BMC Mixer

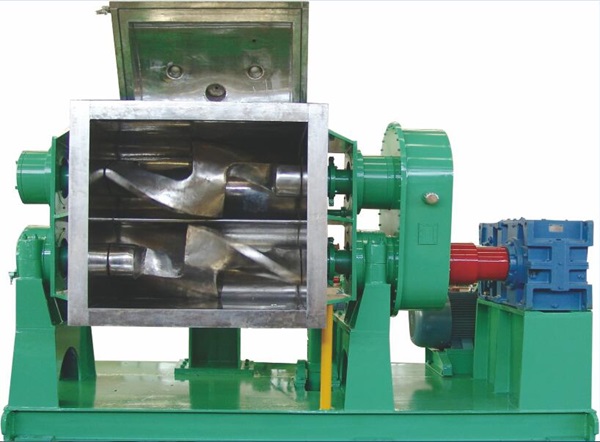

BMC kneading machine generally adopts double Z-type kneading blades, which rotate relative to each other at different speeds. After the raw materials enter the kneading tank:

1. The resin and powder are quickly stirred to form a viscous matrix.

2. The glass fiber is evenly dispersed under the action of shearing and flipping to prevent knotting or stratification.

3. The jacket cooling system controls the material temperature to prevent premature solidification.

4. After the material reaches the set time and uniformity, it is discharged through hydraulic flipping cylinder or screw extrusion and enters the following process.

This principle, combined with high shear, flipping, and kneading, can quickly complete the uniform mixing of BMC and control its processing performance.

Main Structure of the BMC Kneading Machine

• Kneading chamber: carbon steel or stainless steel, wear-resistant inner wall.

• Kneading blades: double Z-type or double spiral type, shearing and mixing at different speeds.

• Drive system: reducer + motor combination, providing mighty power.

• Temperature control system: jacketed water cooling structure, precise temperature control.

• Discharging system: hydraulic cylinder turning or screw extrusion, adapting to different discharging methods.

Equipment Features of the BMC Mixer

• Uniform mixing: double Z blade structure, ensuring complete and uniform mixing of glass fiber, filler, and resin.

• Vigorous kneading: adapt to high viscosity and filling system, for more uniform glass fiber distribution.

• Precise temperature control: a jacket cooling system that prevents overheating and curing materials.

• Convenient operation: hydraulic cylinder turning or automatic discharging, improving production efficiency.

• Sturdy and durable structure: suitable for long-term stable operation.

• Strong adaptability: parameters such as blade speed and cylinder capacity can be customized according to the BMC formula.

Applications

Applicable to the mixed preparation of BMC raw materials, widely used in the following product production lines:

♣ BMC molded manhole covers

♣ Electrical insulation parts

♣ Auto parts (such as bumpers, battery boxes)

♣ Bathroom accessories (such as wash basins, bathtub brackets)

♣ Lamp bases and other BMC products

TechnoFRP is a professional BMC mixer manufacturer in China that provides high-quality BMC kneading machines and BMC products. We can also design a whole production line to meet your needs.

Post time: Jun-25-2025