Sectional GRP Water Tank Panel

GRP sectional water tank panels are made of glass fiber as the main reinforcement material through compression molding technology, with a focus on high strength and long-term durability. Compared with FRP water tank panels, GRP panels usually perform better in mechanical properties and anti-seepage properties, and are particularly suitable for scenarios with high pressure or special water storage needs, such as water supply in high-rise buildings or chemical storage in the industrial field. GRP water tank panels emphasize modularization and customization, and are suitable for high-demand scenarios, providing customers with more stable and durable water storage solutions.

As a GRP water tank supplier in China, TechnoFRP provides high-quality GRP sectional water tank panels. At the same time, we also provide a complete production line solution for water tank panels.

Features of GRP sectional water tank panels

1. High strength and lightweight

The GRP water tank plate is reinforced with glass fiber, which is significantly stronger than traditional metal or plastic materials. It can significantly reduce the weight while ensuring the load-bearing capacity, making it easy to transport and install.

2. Excellent corrosion resistance

The panel has excellent corrosion resistance to chemicals such as acids, alkalis, and salts, and is suitable for storing drinking water, industrial water, or other chemical liquids.

3. Long-lasting weather resistance

GRP material has excellent UV resistance and anti-aging properties, is suitable for use in various extreme environments, and has a service life of more than 20 years.

4. Health and safety

The inner and outer surfaces of the board are smooth and dense, easy to clean, do not breed bacteria, and meet the hygienic standards for drinking water storage to ensure the safety of water quality.

5. Modular design

The panels are produced in standardized sizes and can be flexibly assembled into water tanks of different capacities and shapes to adapt to various site requirements.

Production process of GRP water storage tank panel

1) Raw material preparation:

Use high-strength glass fiber, unsaturated polyester resin, and other reinforcing agents for compounding.

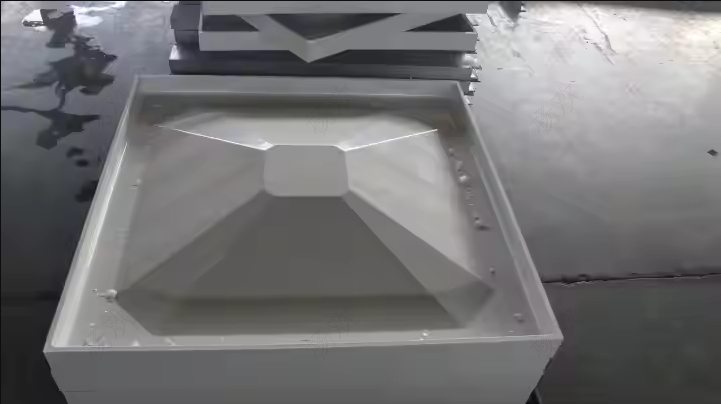

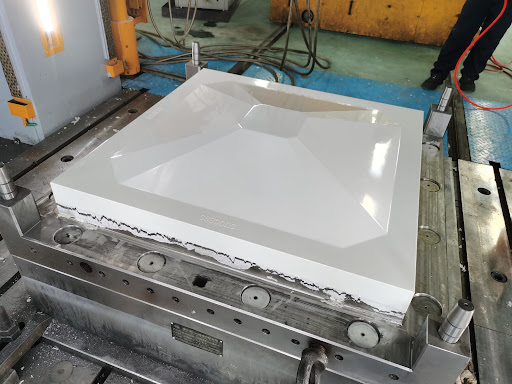

2) Compression molding:

Use special molds and hydraulic molding machines to press the sheet under high temperature and high pressure to ensure its dimensional accuracy, surface finish, and internal density.

3) Post-processing and inspection:

After molding, the sheet is processed by drilling, cutting, etc., and passes strict inspections of sealing and mechanical properties.

Application of GRP horizontal water tank panel

• Domestic water supply:

Water storage equipment for water supply systems in residential, and commercial buildings, schools, hospitals, etc.

• Fire water storage:

Used in emergency fire water tanks to provide highly reliable water reserves.

• Industrial water:

Liquid storage systems in chemical, food processing, pharmaceuticals, etc., are especially suitable for corrosive liquid storage.

• Agricultural irrigation:

Used for long-term water storage in agricultural water storage and irrigation systems.

Sectional GRP water tank panel sizes

1. The size of FRP/GRP panels are produced by standard mold, having sizes 1*1m,1*0.5,m, and 0.5*0.5m.

2. The panel thickness depends on tank height.

3. The available highest height is 5 meters (Add external C channel or I-beam reinforcement for 4m and 5m height).

|

SIZE OF PANEL |

WEIGHT OF EACH PANEL |

||||||||

|

5# |

8# |

10# |

12# |

14# |

16# |

18# |

20# |

22# |

|

|

1*1m |

12kg |

17.5kg |

21kg |

25kg |

29kg |

33kg |

37kg |

41kg |

44kg |

|

1*0.5m |

7kg |

9kg |

11kg |

13kg |

15kg |

17kg |

19kg |

21kg |

23kg |

|

0.5*0.5m |

4.5kg |

4.8kg |

5.8kg |

6.7kg |

7.5kg |

8.5kg |

9.5kg |

/ |

/ |

|

TANK HEIGHT (mm) |

THICKNESS OF EACH PANEL |

||||||

|

Bottom |

1st layer |

2nd layer |

3rd layer |

4th layer |

5th layer |

Roof |

|

|

1000 |

10# |

10# |

/ |

/ |

/ |

/ |

5# |

|

1500 |

10# |

10# |

8# |

/ |

/ |

/ |

|

|

2000 |

12# |

10# |

8# |

/ |

/ |

/ |

|

|

2500 |

12# |

12# |

10# |

8# |

/ |

/ |

|

|

3000 |

14# |

12# |

12# |

8# |

/ |

/ |

|

|

3500 |

16# |

14# |

12# |

10# |

8# |

/ |

|

|

4000 |

18# |

18# |

14# |

12# |

10# |

/ |

|

|

4500 |

20# |

18# |

14# |

12# |

10# |

8# |

|

|

5000 |

22# |

20# |

16# |

12# |

10# |

8# |

|

GRP water tank panel specifications

| Material | GRP/FRP/SMC |

| Size | 1x1m, 1.5x1m, 1×0.5m |

| Panel Shape | Ball shape |

| Thickness | 20mm-12mm-10mm-8mm-6mm-4mm depending on the water tank size and height |

| Remarks | Thickness Tolerance: ±0.2mm |

| Volume | From 1m3 to 1000m3 |

| COLOR | White, Blue, and so on |

| SMC water tank physicaland chemical properties | ensile strength (Mpa)≥60 |

| Bending strength (Mpa)≥100 | |

| Bending modulus (Gpa)≥7.0 | |

| Pap hardness≥60 | |

| Bibulous rate,%≤1.0 | |

| Glass fiber content,%≥25 | |

| Leakage | No leakage after filled with water |

| Fittings | ladder, support, timepiece,u channel base, flange, plug, screws, nuts |

| Water quality | Accord with GB5740 |

| Packaging Detail | regular packed by pallet and wooden case |

| Delivery Detail | Water tank lead within 7-15days |