SMC (Sheet Molding Compound) sheet is a composite material composed of unsaturated polyester resin, glass fiber, filler and other additives, which is widely used in automobiles, construction, electrical equipment and other fields. The molding process of SMC sheet mainly includes compression molding, injection molding, transfer molding, etc. This article will introduce the principles, characteristics and applications of these molding processes in detail.

Compression molding process

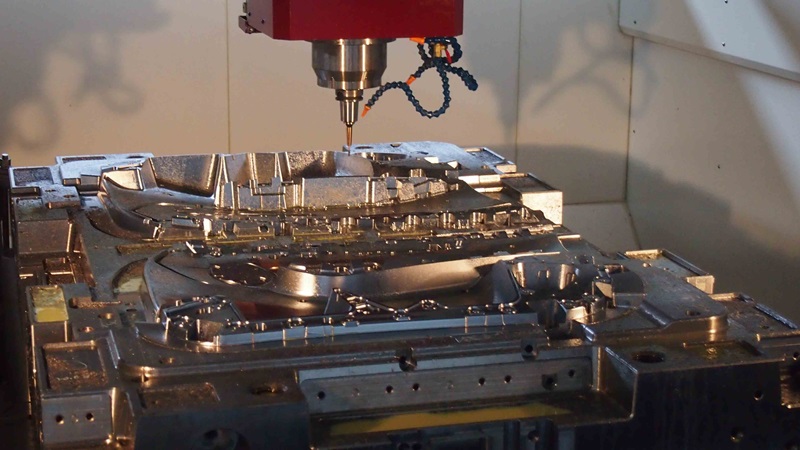

Compression molding is one of the commonly used molding processes for SMC sheets. Its basic principle is to put the pre-prepared SMC sheet into a heated mold, apply pressure to make it flow in the mold and fill the entire cavity, and then solidify and mold.

Compression molding process flow:

1. Prepare the SMC sheet: Cut the SMC sheet to the appropriate size according to product design requirements.

2. Preheat mold: Heat the mold to the molding temperature, usually between 120°C and 160°C.

3. Place sheet: Place the cut SMC sheet into the mold.

4. Mold closing and pressurization: close the mold and apply pressure to make the SMC sheet flow in the mold and fill the cavity.

5. Curing molding: maintain pressure and time to solidify the SMC sheet in the mold.

6. Demolding: open the mold and take out the molded product.

Compression molding process characteristics:

- Advantages:

The molding pressure is low, and the equipment investment is relatively small.

Suitable for products of large sizes and complex shapes.

The molding cycle is short, and the production efficiency is high.

- Disadvantages:

The mold design and manufacturing requirements are high.

The surface quality of the product is greatly affected by the surface finish of the mold.

Application of compression molding process:

Compression molding is widely used in automotive body parts, building decorative panels, electrical equipment housings and other fields.

Injection molding process

Injection molding involves heating the SMC sheet to a molten state and injecting it into the mold through an injection machine.

Injection molding process flow:

1. Prepare SMC sheet: Heat the SMC sheet to a molten state.

2. Injection: Inject the molten SMC material into the mold through an injection machine.

3. Fill the cavity: The molten SMC material flows into the mold and fills the entire cavity.

4. Curing molding: Maintain pressure and time to allow the SMC material to solidify in the mold.

5. Demolding: Open the mold and take out the molded product.

Features of the injection molding process:

- Advantages:

High molding pressure is suitable for products with high precision and complex shapes.

Good product surface quality.

Short molding cycle and high production efficiency.

- Disadvantages:

Large equipment investment;

High requirements for mold design and manufacturing.

More material waste.

Application of injection molding process:

Injection molding is widely used in automotive interior parts, electronic equipment housings, medical devices and other fields.

Transfer molding process

Transfer molding is a method of transferring the SMC sheet to a molten state and then transferring the material to the mold through a transfer molding machine for molding.

Transfer molding process flow:

1. Prepare SMC sheet: Heat the SMC sheet to a molten state.

2. Transfer: Transfer the molten SMC material to the mold through a transfer molding machine.

3. Fill the cavity: The molten SMC material flows into the mold and fills the entire cavity.

4. Curing molding: Maintain pressure and time to allow the SMC material to solidify in the mold.

5. Demolding: Open the mold and take out the molded product.

Characteristics of transfer molding process:

- Advantages:

High molding pressure is suitable for products with high precision and complex shapes.

Good product surface quality.

Short molding cycle and high production efficiency.

- Disadvantages:

Large equipment investment.

High requirements for mold design and manufacturing.

More material waste.

Application of transfer molding process:

Transfer molding is widely used in automotive interior parts, electronic equipment housings, medical devices and other fields.

Other molding processes

In addition to the above main molding processes, SMC sheets can also be formed by other molding methods, such as pultrusion, winding, etc.

Pultrusion: The SMC sheet is pulled through a heated mold to form a continuous long strip product. Suitable for the production of pipes, profiles, etc.

Wrapping: The SMC sheet is wound on the core mold, heated, and cured. Suitable for the production of cylindrical, spherical and other products.

Features:

- Advantages:

Suitable for the production of continuous long strips or cylindrical products.

High production efficiency.

High product strength.

-Disadvantages:

Large equipment investment.

High requirements for mold design and manufacturing.

More material waste.

Application:

Pultrusion and winding are widely used in pipes, profiles, storage tanks and other fields.

There are many different molding processes for SMC sheets, each with unique advantages and scope of application. Compression molding is suitable for products with large sizes and complex shapes; injection molding and transfer molding are ideal for products with high precision and complex shapes; pultrusion and winding are suitable for producing continuous long strips or cylindrical products. Choosing the proper molding process can significantly improve product quality and production efficiency and reduce production costs. With the constant advancement of technology, the molding process of SMC sheets will become more diversified and efficient, providing more possibilities for applications in various fields.

Techno provides SMC sheet machines and various other SMC sheet molding equipment. If you have any needs, please contact us.

Post time: Jun-10-2025